阅读次数: 次 发布日期:2020-05-21

无锡航一机械有限公司 WUXI HY MACHINERY CO., LTD.

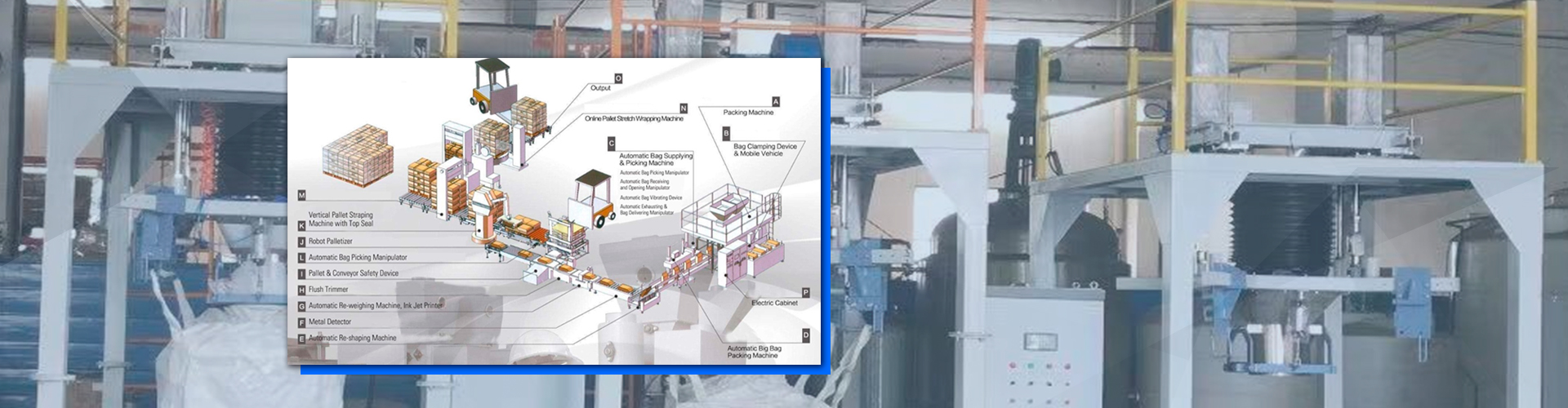

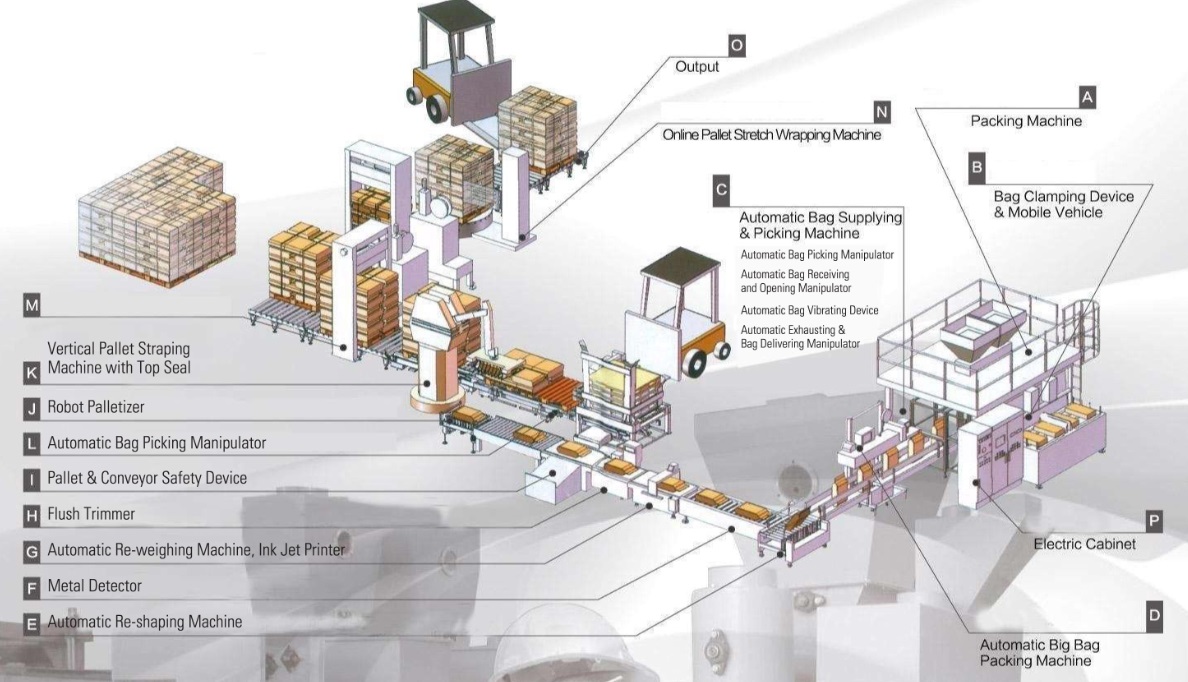

Fully Automatic Packing & Palletizing Line

Fully Automatic Packing Palletizing Line

Fully Automatic Packing Line

Fully Automatic Bagging Line

Fully Automatic filling and packaging line

Automated bagging system automatic bagging, palletising and wrapping line

Produced by WUXI HY MACHINERY CO., LTD. 无锡航一机械有限公司

Applications:

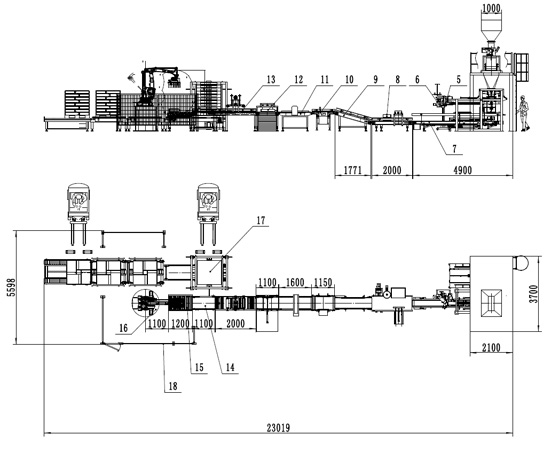

This is Fully Automatic Packing Palletizing Line, Fully Automatic Packing Line, Fully Automatic Bagging Line, Fully Automatic filling and packaging line, automated bagging system produced by WUXI HY MACHINERY CO., LTD. This fully automatic packing line includes automatic bags placing feeder, auto materials feeding filling, auto weighing bagging, auto bags guide-in and bag top sealing, auto bags transportation conveyor, auto empty pallet feed-in before robot, auto robot palletizing with pallet dispenser for stacking on pallet, loaded pallet conveyor, auto pallet wrapping, etc.. It's fully automatic finished and continuously working.

And it's selectable to install the bag overturning, reshaping, flattener, weight re-checker, metal detector, rejection system, printer, palletizer, etc. to make a complete automatic bagging production line produced by Wuxi HY Machinery Co., Ltd. Contact us by kingmoon0523@hotmail.com We Wuxi HY Machinery Co., Ltd. will be pleased to support you at any time.

Technical Parameters

Model: LCS-HYA series

Working location: Indoor

Weighting Range: 1~100kg, customized

Accuracy: +/-0.2%

Capacity: 180-220bags/hour, 300-360bags/hour, 500-700bags/hour, 700-1000bags/hour

Power Supply: AC110-240V/220-600V, 50/60Hz, 1/3P, customized made as per local electrical system

Power: 10~18 kW, depends on packing speed capacity & the matching devices.

Air Resource: 0.55~0.65Mpa, 6bar;

Air Consumption : ~100 Nm3/h

Bag Belt Conveyor Dimension: 5000*400mm, customized design.

Main part

Bag Supplying Machine

About 200 empty bags are put in 2 horizontal plates (the number of empty bags depends on the bag thickness), and bag supplying is finished by vacuum chuck. After one empty bag taken, the plate with many empty bags moves to the bag fetch position so that the equipment can run continuously and stably, produced by Wuxi HY Machinery Co., Ltd.

Bag Position Adjustment

Adjust the whole position of empty bag.

Take Empty Bag

Take the empty bag of Bag Supplying Machine.

Horizontal Movement

Move the empty bag to feed opening.

Open Empty Bag

Move the empty bag to feed opening, then open the pocket mouth of bag with vacuum chuck.

Bag Clamping and Feeding Mechanism

The empty bag is clamped by Bag Clamping Mechanism under the feed opening, then feeding door insert to the bag and start the feeding.

Transitional Hopper & Twice Feeding Door

The Transitional Hopper is the transitional part between the Metering Mechanism and Packaging Machine. The Twice Feeding Door’s main function is to be a cushion during feeding materials, so that reduce the air content in materials.

Bag Bottom Flapping Mechanism

After the materials filled the bag, the mechanism claps the bottom of bag to make materials fully drop down the bottom of bag.

Bag Horizontal Moving & Pocket Mouth Clamping Mechanism

The bag with materials is put on the Standing Bag Conveyor from feed opening, and clamped by the Pocket Mouth Clamping Mechanism until get to the sealing part

Standing Bag Conveyor

The bag with materials is conveyed at the same speed, and the conveyor height can be changed with height regulating handle.

And it’s selectable to install the bag overturning, reshaping, flattener, weight re-checker, metal detector, rejection system, printer, palletizer, etc. to make a complete automatic bagging production line produced by Wuxi HY Machinery Co., Ltd.

Robot palletizing machine

Description

Robot palletizer adopts advanced palletizing robot for stacking. Simple structure, small covering space, simple operation, low power consumption and easy maintenance. Using touch-screen operation.

Robot palletizer is widely used in the packaging machinery industry. The latest robot palletizing machine has the features of simple structure, small size, light weight, faster speed, more safety, energy-saving, good looking, less power, etc. And it can significantly shorten the length of the production line, reduce the amount of equipment and simplify the work procedures. Through setting, the robot will be able to complete the task of discharging and palletizing nylon (paper) bags, plastic bag, cardboard box, plastic containers, glass bottles, etc.

Technical Parameters:

Model: ABB / Kawasaki / Estun

Grasping scope: 10-50kg bag, customized as per requirement

Palletizing capacity: customized, matching with the automatic packing machine line.

The mechanical structure: Multi-joint robot

Action mode: cylindrical coordinate type

Grasping hand: finger type

Stacking memory capacity: standard 30 kinds (up to 400 kinds)

Stack height: max.2300mm

Stack width: max.1500mm

Control Method : PLC

Square area: L 2000mm×W4000mm

Stack type structure: customized

Stack form: According to the user's needs, single/double station.

Service

1. Project analysis

According to your product specifications and packing requirements, in order to guarantee the packing speed and accuracy, we will analyse your products and your bags after receipt of your inquiry to select the right filling technology for your project in close cooperation with you. And our solution will be the perfect combination of product, packing material and machine.

Product analysis:

- Mesh size

- Corrosivity

- Bulk density

- Flowability

- Humidity

- Feeding methods

Our practice-orientated tests lead to economic packaging solutions, customized design for your individual needs, and facilitate the collection of process-relevant product data. So you can be assured that your products will fulfill your customers in the desired quality day after day.

2. Technical customer service

Our service does not end with the delivery of your new packaging plant. We offer a wide range of after-sales services, e.g. commissioning of your machine or later regular maintenance of your packaging plant.

A team of well-trained service technicians is at your disposal. They all have extensive experience with packaging technologies in combination with different products and bags all over the world.

Contact us by kingmoon0523@hotmail.com We Wuxi HY Machinery Co., Ltd. will be pleased to support you at any time.

3. Spare parts

Lifetimes of machines are largely influenced by the quality of the used components. Thanks to an extensive stock of spare parts we are able to supply original spare parts fast at short notice.

You profit from using original parts: Optimally fitting into the machines they guarantee highest outputs and lifetimes.

4. Safety engineering

The safety of our supplied machines and plants is one of our top priorities. Thus, part of our essential goals is to best help you avoid damage caused by machines and ensure maximum safety for your personnel. In addition, there is a large number of safety guidelines regulated by law that have to be considered when constructing machines. We support you in developing the right safety concept for your packaging project, produced by Wuxi HY Machinery Co., Ltd.

无锡航一机械有限公司 全自动包装码垛线

全自动包装码垛线 全自动包装线 全自动装袋线 全自动灌装包装线 自动装袋系统 自动装袋机 由无锡航一机械有限公司生产。

应用:

这是无锡航一机械有限公司生产的全自动包装码垛线、全自动包装线、全自动装袋线、全自动灌装包装线、自动装袋系统。进料灌装、自动称重装袋、自动进袋和袋顶封口、自动袋输送输送机、机器人前自动空托盘进料、带托盘分配器的自动机器人码垛在托盘上堆垛、装载托盘输送机、自动托盘包装等。全自动完成,连续工作。

并可选择安装翻袋机、整形机、压平机、重检机、金属检测机、剔除系统、打印机、码垛机等,组成无锡航一机械有限公司生产的一条完整的全自动装袋生产线。

技术参数

型号:LCS-HYA系列

工作地点:室内

称重范围:1~100kg,定制

准确度:±0.2%以内

产能:180-220袋/小时、300-360袋/小时、500-700袋/小时、700-1000袋/小时

电源:AC110-240V/220-600V,50/60Hz,1/3P,根据当地电气系统定制

功率:10~18kW,视包装速度容量及配套设备而定。

气源:0.55~0.65Mpa,6bar;

耗气量 : ~100 Nm3/h

袋带输送机尺寸:5000*400mm,定制设计。

主要部分

送袋机

约200个空袋装在2个水平板中(空袋数量视袋厚而定),由真空吸盘完成供袋。取一个空袋后,带多个空袋的盘子移动到取袋位置,使设备连续稳定运行,无锡航一机械有限公司生产。

袋位调整

调整空袋整体位置。

拿空包

取出供袋机的空袋。

水平移动

将空袋移至进料口。

打开空袋

将空袋移至进料口,然后用真空吸盘打开袋口。

夹袋送料机构

空袋由进料口下方的夹袋机构夹住,然后进料门插入袋中并开始进料。

过渡料斗和二次进料门

过渡料斗是计量机构和包装机之间的过渡部分。双进料门的主要作用是在进料过程中起缓冲作用,减少物料中的空气含量。

袋底拍打机构

物料装满袋子后,该机构拍打袋底,使物料完全落下袋底。

袋横移袋口夹紧机构

装有物料的袋子从进料口放到立袋输送机上,由袋口夹紧机构夹紧,直至到达封口部位

立袋输送机

装有物料的袋子以相同的速度输送,输送高度可通过高度调节手柄改变。

并可选择安装翻袋机、整形机、压平机、重检机、金属检测机、剔除系统、打印机、码垛机等,组成无锡航一机械有限公司生产的一条完整的全自动装袋生产线。

机器人码垛机

描述

机器人码垛机采用先进的码垛机器人进行码垛。结构简单、占地面积小、操作简单、功耗低、维护方便。采用触摸屏操作。

机器人码垛机广泛应用于包装机械行业。最新款机器人码垛机具有结构简单、体积小、重量轻、速度快、更安全、节能、美观、省电等特点,可显着缩短生产线长度,减少设备数量,简化工作程序。通过设置,机器人将能够完成尼龙(纸)袋、塑料袋、纸箱、塑料容器、玻璃瓶等的卸料和码垛任务。

技术参数:

型号:ABB/川崎/埃斯顿

抓取范围:10-50kg袋装,按要求定制

码垛能力:定制,与自动包装机线匹配。

机械结构:多关节机器人

动作方式:圆柱坐标式

抓手:指型

堆叠记忆容量:标准30种(最多400种)

堆叠高度:max.2300mm

堆叠宽度:max.1500mm

控制方式:PLC

方形面积:L 2000mm×W4000mm

堆栈类型结构:定制

堆叠形式:根据用户需要,单/双工位。